Process Vacuum System Design And Operation

Process vacuum system design and operation. Digesters may be operated as a batch process or as a continuous-feed process. Business Process Co-Operation View. Design Operation And Analysis Of Waste Water 25 Integrated Fixed Film Activated System IFAS addition of fluidized bio-media has been implemented to meet these requirementsThis hybrid process of fluidized media and activated sludge process taking place in a single aeration tank is known as Integrated Fixed Film.

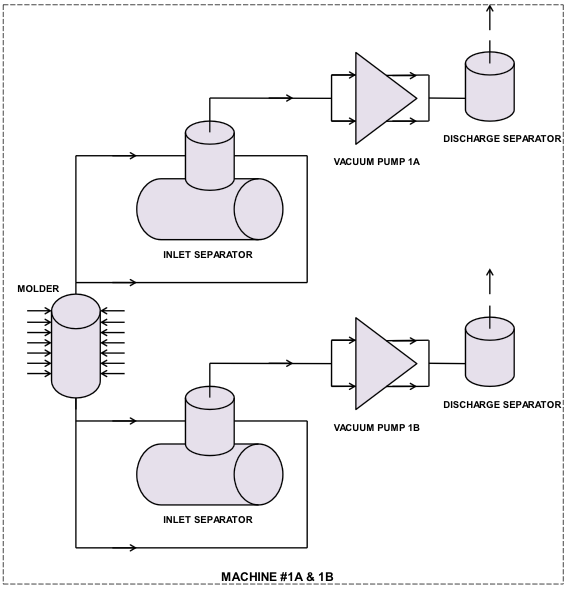

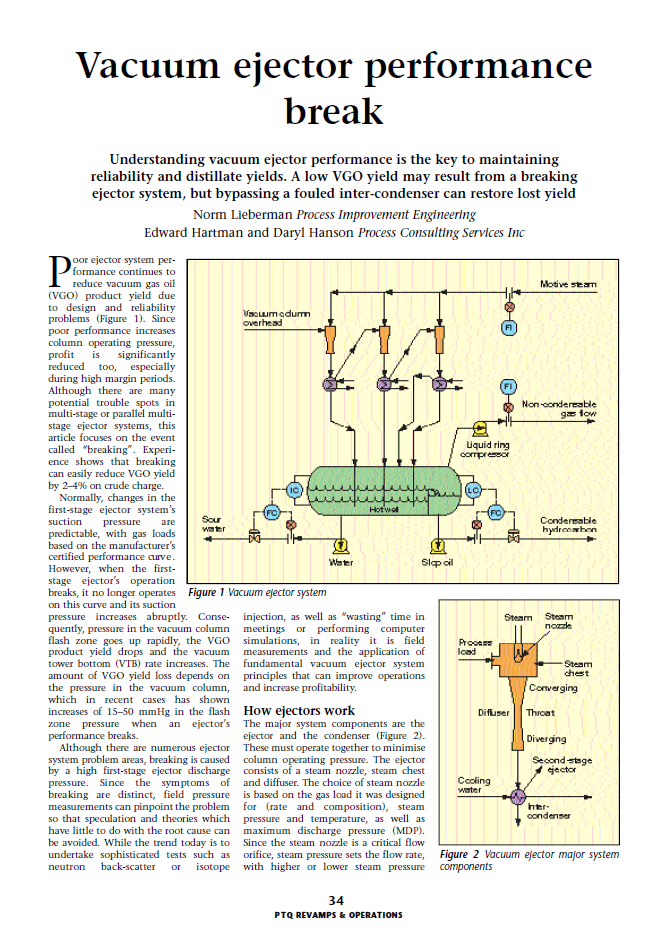

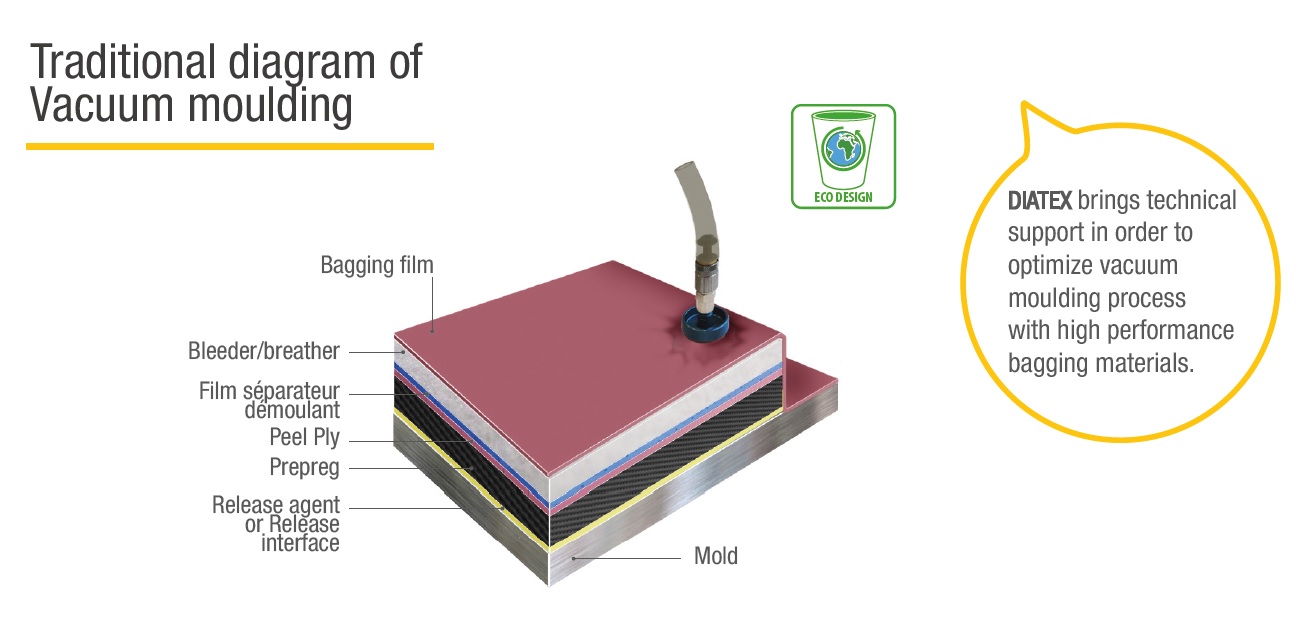

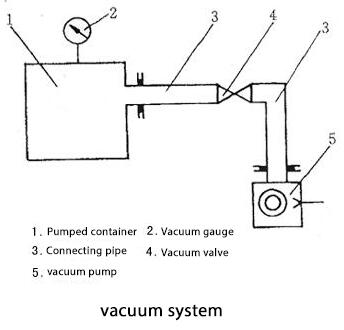

The most important step in any diagnostic process is understanding the system design the specific components used and its theory of operation. Disadvantages of this approach are the need for operator assistance in a semi-automated operation and a slower production rate than a fully automated system. Depending on local environmental constraints these systems can be used for.

This article will provide an overview of the different systems and in the case of the vacuum-based system the evolution of design enhancements used to comply with the 020-in. The work package Tritium Matter Injection Vacuum TFV is within the EUROfusion Consortium responsible for the EU-DEMO that will be simply called DEMO in this paper fuel cycle development in line with the European Research. Business Process Diagram Example.

Ruags analysis however shows that given the relatively low production rate these disadvantages are well offset by the advantages of parts consolidation low equipment cost and nearly unlimited. Flare System Design for Oil and Gas Installations Design Requirements for a Flare System Flare systems provide for the safe disposal of gaseous wastes. Pedigree Chart 7 See All Pedigree Chart Example 1.

Design infographic flyer posters gift cards logos certificates menus resumes. Production operations management Chapter 5 Product Process design 2. Product Design can be defined as the idea generation concept development testing and manufacturing or implementation of a physical object or service.

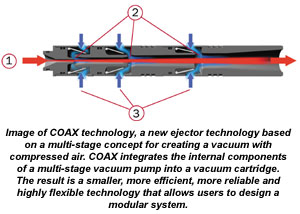

Redefining Vacuum Vacuum became a valuable industrial tool in the 20th century with the introduction of incandescent light bulbs and vacuum tubes and a wide array of vacuum technologies have since become available. Effluent Treatment Plant. Used for removing sludge are an inclined auger conveyor driven by an external power source or the suction line from a vacuum-type tank.

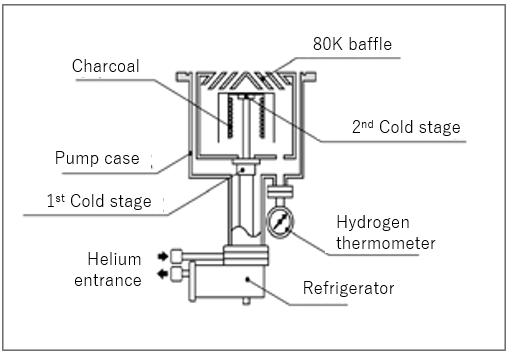

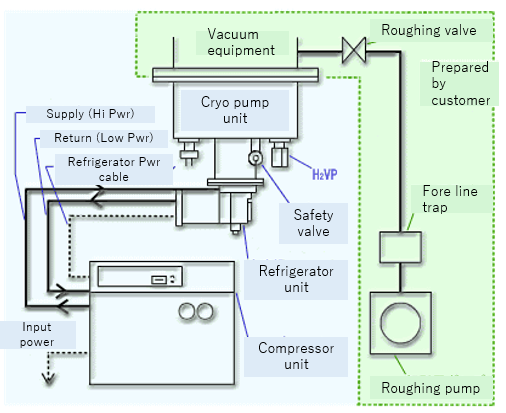

It is a built-in vacuum that allows the whole process of vacuum to be easier and efficient. Turbomolecular pumps are highly compact and when combined with a dry primary pump do not backstream oil into the vacuum system.

Product and process design 1.

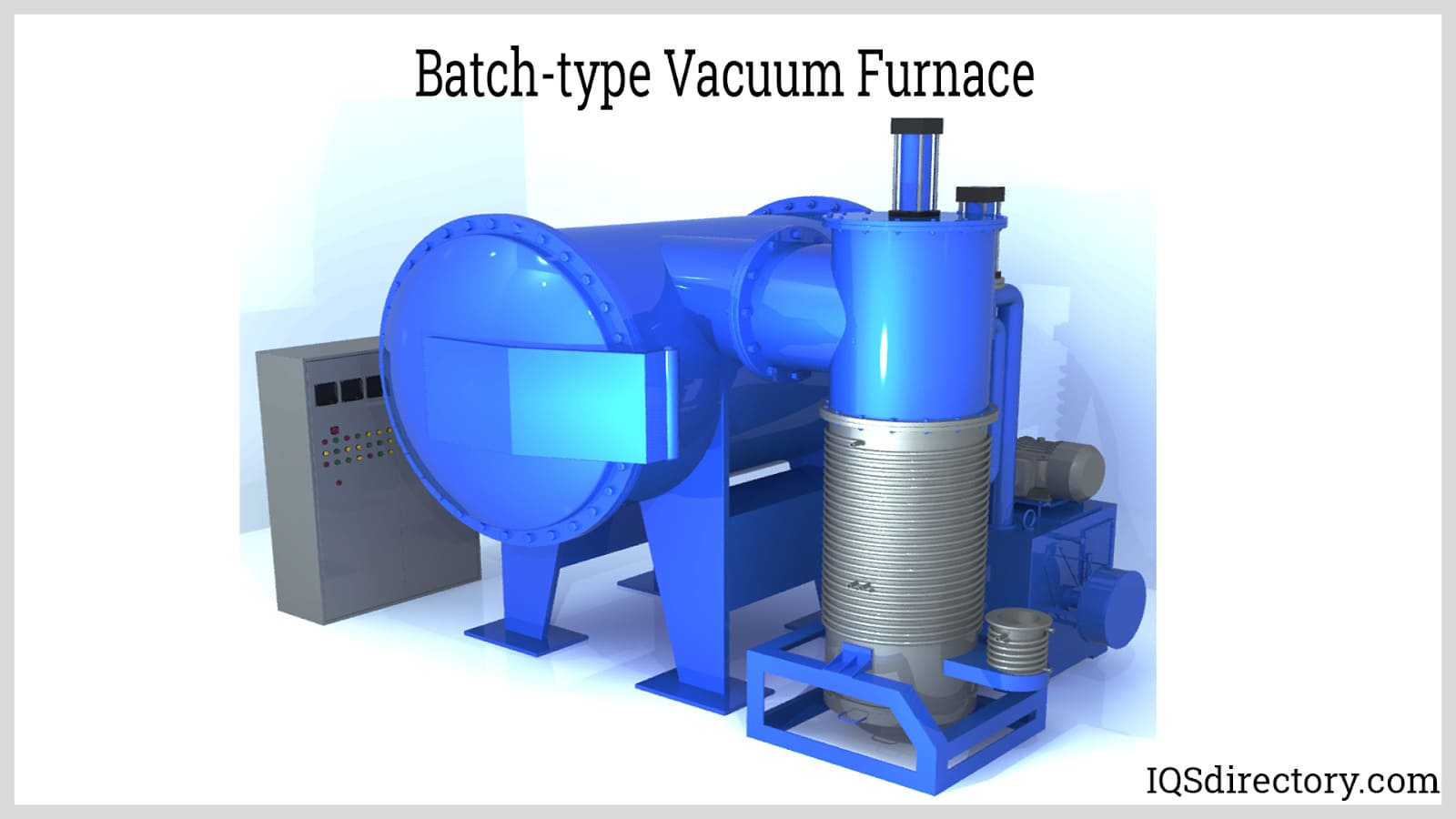

Design and operation of a. In the batch system the. Design Operation And Analysis Of Waste Water 25 Integrated Fixed Film Activated System IFAS addition of fluidized bio-media has been implemented to meet these requirementsThis hybrid process of fluidized media and activated sludge process taking place in a single aeration tank is known as Integrated Fixed Film. Ludwigs classic text to further enhance its use as a chemical engineering process design manual of methods and proven. They provide a low vibration hydrocarbon-free operation which requires no regeneration. They provide constant pumping speeds of up to 4000 ls in the High Ultra-high and Extreme High Vacuum ranges. Everest today has dedicated itself to the manufacturing of world-class vacuum pumps to be used in such applications and support its. Trickling filter process can define as the biological system which tends to separate or degrade the maximum organic and inorganic waste up to 85 out of the primary or raw sludge via the slime layerThe designing. Gas vapor leak standard.

Ruags analysis however shows that given the relatively low production rate these disadvantages are well offset by the advantages of parts consolidation low equipment cost and nearly unlimited. High-level challenges in fuel cycle development for DEMO11. Business Process Diagram Example. Product and process design 1. Pedigree Chart 7 See All Pedigree Chart Example 1. Production operations management Chapter 5 Product Process design 2. Digesters may be operated as a batch process or as a continuous-feed process.

Post a Comment for "Process Vacuum System Design And Operation"